Kiln supports (also known as kiln spacers and kiln furniture) are items made from fired clay which were used to support and/or stack raw clay pieces being fired in a kiln and also sometimes to support multiple racks within a kiln so that it could be loaded with more items. They allowed free movement of hot air around the pieces during firing so that they fired evenly.

Common pieces from the historic era (non-Native American) were cone-shaped. Here’s a couple of examples from the 18th Century or thereabouts which are typical of those used by European potters:

[pics from UK Portable Antiquities Scheme database]

They would usually either be arranged in groups of three to form a kind of tripod support, or in groups of four with one cone supporting each corner area of the item. Note that the bottoms are slightly convex so that the area of contact with the items being fired was minimised if several items were to be stacked on top of one another… a pile of dinner plates for example.

As pottery glazing techniques improved and there was a desire to leave the glaze as free from imperfections as possible, the supports were produced with pointed tops and bottoms to further minimise the contact areas. Like these items, which date from the 1850’s:

[pic from Timothy James Scarlett on the Utah Pottery Project Archaeology blog]

Note that those above are trihedral pyramids, each one having three pointed “feet” and are usually known as “spurs” or sometimes “sagger spurs”. As glazing techniques advanced further still and highly decorated pieces were required to be blemish-free, all kinds of purpose-designed supports were used to accommodate pottery of different sizes and shapes. Some of these forms were generally known as stilts or saddles, like these:

[pic from Fine Dictionary website]

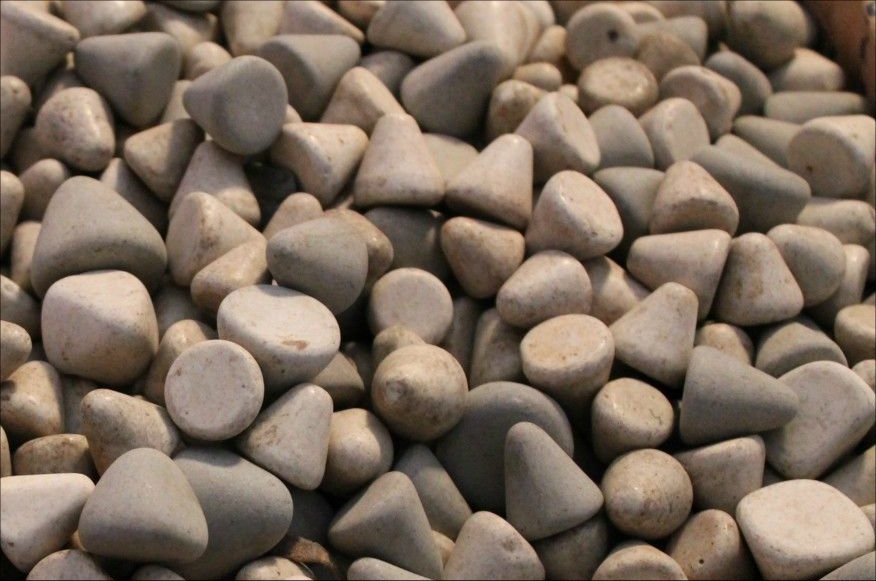

In addition to purpose made cones and such, old lumps of unwanted fired clay were used as shelf supports and spacers for less precious items such as stoneware crocks and jugs. Here’s some examples dating somewhere between 1850-1899 (note that these are glazed):

[pic from AncientPoint website]

NOTE: The cone-shaped items in that picture have a strong resemblance to items used as pottery “anvils” by both Native Americans and early settlers for hand-forming pots. The outside of a block of wet clay in which a cavity had been made would be beaten with a wooden paddle while holding the anvil inside the cavity to thin and shape the walls of the pot. Generally, these anvils have a much more convex bottom, bordering on hemispherical and the general shape may be more mushroom-like and less cone-like. Sometimes, the handle has a couple of “dents” in it to create a hand-grip. Native American items would never be glazed like that.

Leave a comment: